In the realm of precision technology, laser optics stand as a beacon of innovation, driving advancements in numerous industries. At Quartz Solutions Inc., we understand the important role that laser optics play in enhancing performance and efficiency across various applications.

Join us as we unravel the intricacies of laser optics, exploring their unique characteristics, applications, and why Quartz Solutions Inc. is your trusted partner for premium laser optic solutions.

What Makes Laser Optics Different from Normal Optics?

Laser optics encompass a specialized branch of optics tailored to harness the unique properties of laser light. What sets laser optics apart from conventional optics is their ability to manipulate laser beams with precision and efficiency, enabling a wide range of applications across diverse industries?

Whether it’s shaping, focusing, or steering laser beams, laser optics play a pivotal role in optimizing laser systems for maximum performance and reliability.

Unlike conventional light sources, laser light is coherent, monochromatic, and highly directional. This coherence allows laser beams to maintain their phase balance over long distances, resulting in a tight beam with minimal divergence.

Laser Lenses serve as Integral Components in Laser Systems

Laser lenses facilitate the precise control and manipulation of laser beams. These optical components are designed to focus or diverge laser light, depending on the specific requirements of the application.

From collimating lenses to focusing lenses, laser lenses play a crucial role in shaping laser beams for various industrial and scientific applications, including laser cutting, engraving, and medical procedures.

Harnessing the Power of Laser Mirrors

Laser mirrors, another essential component of laser optics, play a vital role in directing and reflecting laser beams with unparalleled precision. These mirrors are engineered to withstand high-power laser beams and maintain their reflective properties across different wavelength ranges.

From cavity mirrors to output couplers, laser mirrors enable precise beam control and manipulation, making them indispensable in laser resonators, interferometers, and beam steering systems.

Applications of Laser Optics

Laser optics find applications across a wide spectrum of industries, ranging from manufacturing and telecommunications to healthcare and scientific research.

Some common applications include:

– Laser Cutting and Welding: Laser optics are used to precisely focus high-power laser beams for cutting and welding various materials, including metals, plastics, and ceramics. Laser optics enable precise beam shaping and focusing to achieve high-precision material processing with minimal heat-affected zones.

– Laser Marking and Engraving: Laser optics enable precise control over laser beams for marking and engraving applications in industries such as automotive, electronics, and jewelry.

– Laser Spectroscopy: Laser optics play a crucial role in spectroscopic techniques for chemical analysis, environmental monitoring, and material characterization.

– Medical Lasers: Laser optics are utilized in medical procedures such as laser eye surgery, dermatology, and dentistry. They are used for precise tissue ablation, optical coherence tomography (OCT), and laser therapy, offering minimally invasive treatment options with high precision and efficacy.

– Telecommunications: In telecommunications, laser optics are used in fiber optic communication systems for signal transmission and amplification. Optical fibers, laser diodes, and optical amplifiers are key components that rely on laser optics for efficient signal processing and transmission over long distances.

– Scientific Research: Laser optics are indispensable tools in scientific research, enabling a wide range of applications such as laser spectroscopy, microscopy, and holography. They facilitate precise control and manipulation of laser beams for experimental setups, allowing researchers to study and explore various phenomena in physics, chemistry, and biology.

– Defense and Security: Laser optics find applications in defense and security systems for target designation, range finding, and laser weapons. They are used in laser rangefinders, target designators, and directed energy weapons, providing accurate and effective solutions for military and law enforcement applications.

Materials and Coatings in Laser Optics

In laser optics, protective windows and lenses are commonly crafted from high-purity synthetic materials, natural quartz glass, and optical-grade materials like sapphire. These materials are chosen for their excellent optical properties, including high transmission rates and durability.

Additionally, anti-reflective coatings (AR coatings) are frequently applied to optical glasses and lenses to minimize surface reflections. These coatings contribute to improved visual quality by reducing glare and increasing light transmission. By employing the right materials and coatings, laser optics can effectively enhance the performance and reliability of laser systems across various applications.

Manufacturing Processes of Laser Optics

The production of laser optics components involves a series of intricate manufacturing processes, each aimed at achieving precise optical surfaces and properties necessary for optimal laser performance.

1. Precision Machining:

Precision machining is the initial step in manufacturing laser optics components. This process involves the shaping of raw materials into precise geometries using computer-controlled machining tools such as lathes, mills, and CNC (Computer Numerical Control) machines.

Manufacturers utilize high-precision machining techniques to achieve the exact dimensions and tolerances required for optical components such as lenses, mirrors, and prisms.

2. Polishing:

After machining, optical components undergo polishing to attain smooth and optically flat surfaces. Polishing involves the removal of surface imperfections, scratches, and irregularities through abrasive materials and precision polishing techniques.

Advanced polishing methods, such as computer-controlled polishing systems and robotic polishing arms, ensure consistent surface quality and sub-nanometer surface roughness required for laser optics applications.

3. Coating Techniques:

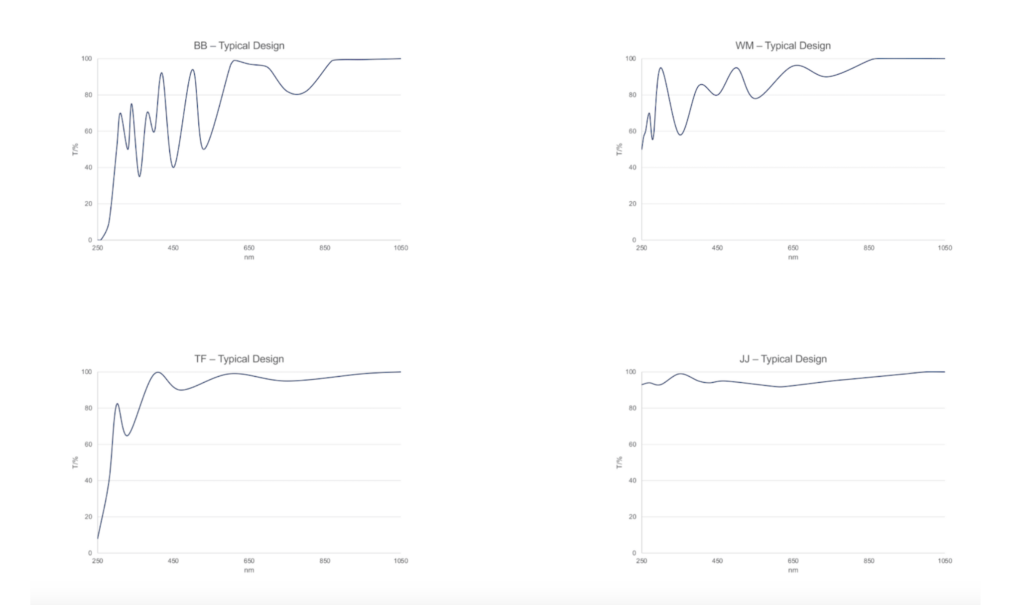

Coating is a critical step in the manufacturing of laser optics components, where thin film coatings are applied to optical surfaces to enhance their optical performance and durability.

Common coating techniques include physical vapor deposition (PVD) and chemical vapor deposition (CVD), which allow for the deposition of thin film coatings such as anti-reflective coatings (AR), high-reflectivity coatings (HR), and dielectric coatings.

What is the Journal Abbreviation for Optics & Laser Technology?

The journal abbreviation for Optics & Laser Technology is “Opt. Laser Technol.” This abbreviation is commonly used in academic publications and scientific literature to reference articles and research papers published in the journal.

Laser Optics Represent a Cornerstone of Modern Technology

Laser Optics enable precise control and manipulation of laser beams for a wide range of applications. With our expertise in laser optics and premium optical components, Quartz Solutions Inc. stands ready to meet your laser optic needs with precision, reliability, and innovation.

Partner with us and unlock the full potential of laser optics for your business.